AI in the manufacturing industry has improved the safety and efficiency of all its operations. One of the popular tools used in manufacturing is Machine Vision. It is used to perform an automated visual inspection on the objects that are manufactured in thousands every day. With the advancements made in Artificial Intelligence, the processes of algorithm development have become superior. Deep learning-based inspection models are often combined with machine vision systems. Such systems are easier to train and implement. Industrial machine vision systems are also more reliable, robust, and stable. They have high mechanical and temperature stability, are of low cost but high accuracy. There are many different applications of Machine Vision in manufacturing. Here are a few of the machine vision applications –

1. Object Detection

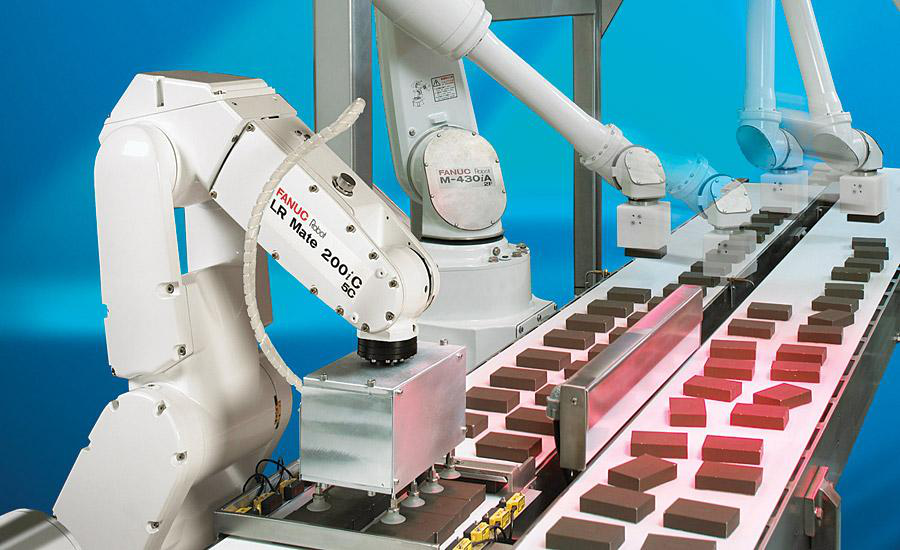

It is a machine vision use case where the Machine Vision aided system looks for individual objects rather than the entire image. The goal of this exercise is to identify different objects inside an image so that it can eliminate objects which are not relevant to the inspection and only focus on the relevant objects. A variety of techniques are used to make object detection as efficient as possible. Object detection is used in many points in the manufacturing industry like an assembly line, sorting, quality management, inventory management, etc. For instance, in the gearbox assembly chain, machine vision analyses the image for specific parts and confirms the presence or absence of such parts in that image.

2. Parts Counting

It is a task that is slow and tedious but doesn’t require a lot of intelligence to do. However, manual operators trying to reach their daily goals might make mistakes while counting and that can cause massive delays in assembling parts. Machine vision can use its object identification algorithm to detect the parts and then count them accurately and quickly. For instance, in the manufacturing chain, machine vision can count the piston rings in a stack with great efficiency.

3. Surface Defect Identification

Surface defect identification is another machine vision application that is an essential step in quality control. Manual identification of surface defects is a tedious task and defects can be missed by human operators as they try to match the supply with the demand. Machine vision can provide the accuracy and efficiency of surface inspection in an easy-to-train model. In manufacturing industries, surface defect inspection can detect defects in casting components, bearings, and different metal surfaces. For instance, packaging defect identification can help identify bad packaging which will cause damage during transport.

4. Print Defect Identification

Print defect identification is the process of detecting anomalies in the prints like inconsistencies in color, text, or pattern. Manual inspection by human operators might lead to oversight that will cause deterioration in the quality of the final product. Machine vision can perform print defect identification using AI and deep learning. This takes care of prints, labels, and packaging prints.